Shapeoko2 T-slot Clamps

03 Dec 2014Now that my Shapeoko has a nice t-slot aluminum bed, I needed some work holding clamps. The great thing about CNC machines and 3d printers is that you can often make parts to improve your machines with the machines themselves.

For any CNC work, it is a must to keep the workpiece held firmly while milling. There are many ways to do this with bolts, tape, metal clamps etc. The slots in the t-slot bed can be positioned inconviently for a particular piece and tape can come undone partway through milling not to mention the occasional tape residue left on the bed. Premade clamps are availaible or printable out of plastic, but I wanted to make at least part of something for the machine with the machine itself.

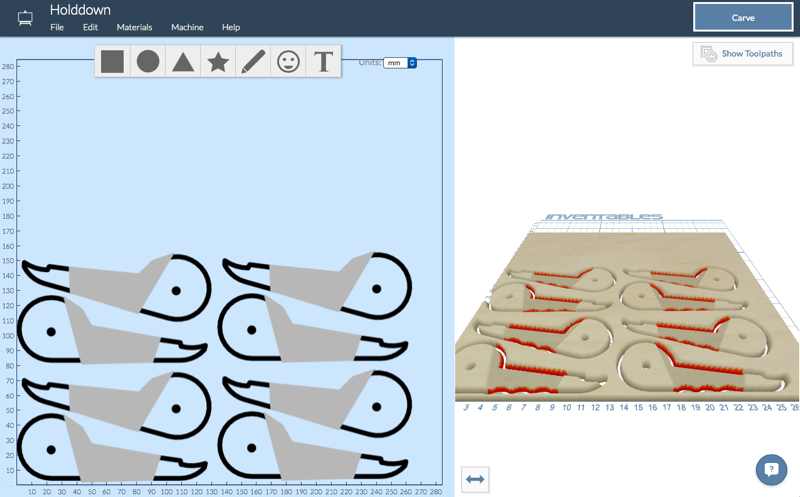

Inventables has created a cam tool specifically for use with the Shapeoko called Easel that’s simple to use. Upload a SVG file, set up the materiel, arrange the parts layout, connect and mill. The CAM functionality of Easel is minimal, no tab support etc, but it works well for more simple jobs and has very easy to follow instructions. Files can be shared with links or published to Inventables.

Creating the cut file was a simple matter of taking a very nice existing clamp design from thingiverse, cleaning up the 2d data, and modifying the design and material settings to match the 9mm MDF I had at hand.

For some reason, Easel marked several areas in red that might be problematic, but after checking the tool paths and the design this was a false warning and I milled the pieces anyway. Milling the clamps (link) was a smooth and trouble-free process. The only quibble I had about Easel besides the lack of tab support was that the tool paths were not optimised very well and resulted in significant wasted movement. Some of that could possible be improved by altering the design, but still the milling took much longer than otherwise necessary.

After cutting, glue the halves together, clamp and let them dry. Next, drill a hole and cut off a short piece (roughly 18mm) of 20mm dowelling. When the glue has dried, add a bolt, washers, a wing nut, and an insertion nut for the t-slots and the clamps will be ready to go. Wooden clamps are great if you happen to make a mistake and run the tool through one, destroying the clamp but saving the end mill (hopefully).

After cutting, glue the halves together, clamp and let them dry. Next, drill a hole and cut off a short piece (roughly 18mm) of 20mm dowelling. When the glue has dried, add a bolt, washers, a wing nut, and an insertion nut for the t-slots and the clamps will be ready to go. Wooden clamps are great if you happen to make a mistake and run the tool through one, destroying the clamp but saving the end mill (hopefully).

Project File

BOM

- 9mm MDF

- 20mm dowel

- M5 bolts

- M5 wingnuts

- Various washers

- HNTTSN6-5 insertion nuts

- Wood glue